About Us

Welcome to Revolution Brass! We are a premier processor of many various cases and calibers. We stock many common cases and are able to get many others in stock. We can always be reached for questions or comments. If you don’t see a caliber you are interested in, please contact us at support@revolutionbrass.com and we will work with you to get you what you need!

Our Process

Preparation

Inspect the Brass Casings: Before cleaning, we inspect the brass casings for any visible dirt, debris, or defects. We Discard any severely damaged or defective casings that may affect the cleaning process.

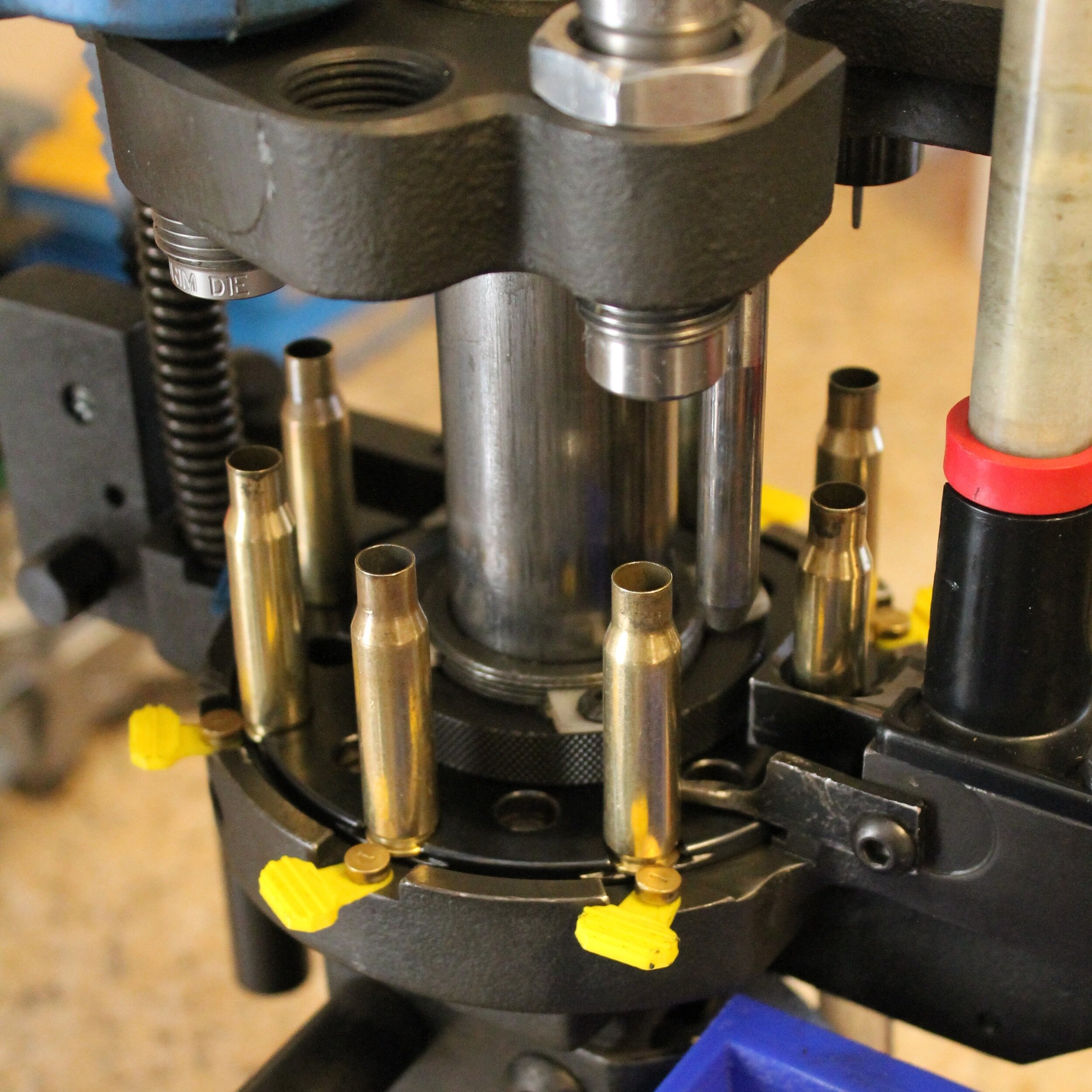

Sorting and Depriming: The brass casings are sorted by caliber to ensure that they are deprimed before cleaning. This step will facilitate a uniform and thorough cleaning process.

Cleaning & Polishing

Brass Polishing Process: The casings are placed in a high-speed rotary tumbler with specially formulated polishing media. Over the course of several hours, the tumbling action effectively removes surface imperfections and imparts a brilliant shine to the brass.

Following the tumbling stage, the casings are carefully rinsed and dried to ensure they are free of any residual polishing media. Our skilled technicians then conduct a final inspection to guarantee that each casing meets our rigorous quality standards.

Upon completion, the polished brass bullet casings emerge with a lustrous finish, ready to enhance the performance and aesthetic appeal of our clients' ammunition products.

Packing

The Packing Process: Once our high-quality polished brass casings have passed through rigorous quality control checks, they are carefully arranged and counted to ensure accuracy. Our experienced team then expertly packs the casings into secure and durable packaging, specifically designed to protect the polished finish during transit.